In today’s fast-moving electronics industry, manufacturers face increasing pressure to reduce costs, shorten product cycles, and deliver compact, high-performance devices. Traditional assembly methods—where separate metal and plastic parts are joined using fasteners, adhesives, or soldering—are no longer efficient or scalable enough for many of these demands. That’s why a growing number of electronics OEMs are turning to insert moulding as a smarter alternative, especially when working with experienced china mold suppliers.

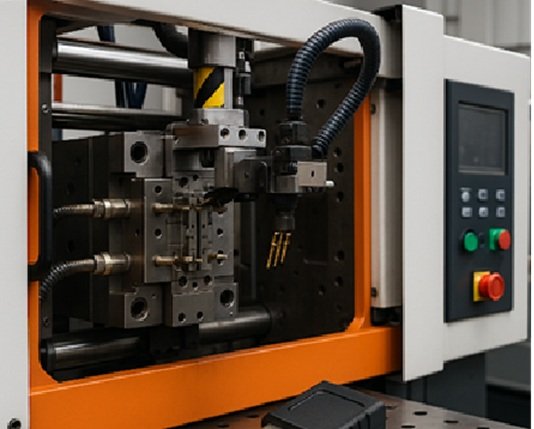

Insert molding allows metal components, such as terminals, bushings, or heat sinks, to be placed directly into a mold cavity before plastic is injected around them. The result is a single, integrated part that combines the benefits of both materials while eliminating multiple assembly steps. This approach is helping manufacturers not only cut production time but also improve product strength, performance, and aesthetics.

Efficiency Gains Over Traditional Assembly

One of the key advantages of insert molding over conventional assembly lies in its streamlined workflow. Traditional methods require multiple stages: creating metal parts, molding the plastic components, aligning and joining them manually or through secondary operations, and finally inspecting for consistency and defects.

With insert molding, all of this is consolidated into a single step. Automated systems can load metal inserts into the mold, where they are securely encapsulated by the plastic resin in a single cycle. This reduces:

- Labor and handling time

- Risks of misalignment or joint failure

- Costs related to adhesives, soldering, or hardware

By eliminating these manual steps, insert molding dramatically increases production throughput while minimizing part variability—critical for electronics applications where precision and reliability are non-negotiable.

Better Product Integrity and Miniaturization

Electronics are getting smaller, thinner, and more complex. Devices like smartphones, wearables, and smart sensors rely on tight internal layouts with minimal room for mechanical fasteners or bulky component housings. Insert molding helps address these space constraints by creating strong, lightweight assemblies with fewer parts.

Because the insert and plastic body are molded together, the final product often has:

- Better mechanical strength at the interface

- Improved resistance to vibration and thermal cycling

- Enhanced sealing or environmental protection

These benefits are especially useful in automotive, consumer electronics, and medical devices, where failure due to loose connections or moisture ingress is not acceptable.

Why Electronics OEMs Are Choosing Chinese Insert Molding Partners

The shift to insert molding has also been driven by advances in global manufacturing capabilities—particularly in China. Many china mold suppliers now offer turnkey insert molding services tailored to the needs of electronics OEMs.

What makes Chinese suppliers appealing?

- Cost-efficiency: Even with automation, insert molding in China remains more affordable than traditional assembly in many high-cost regions.

- Tooling expertise: Insert molding requires high-precision tools and tight tolerances, and leading Chinese molders now compete globally in this area.

- Fast lead times: Thanks to a mature supply chain and localized materials sourcing, Chinese factories can move quickly from prototyping to mass production.

- Design support: Many offer engineering assistance to optimize parts for insert molding from the start, helping avoid delays and redesigns later.

By outsourcing to a capable Chinese partner, OEMs gain access to advanced molding technology without investing in their own tooling infrastructure, allowing them to scale production more flexibly.

Making the Switch

For electronics manufacturers still relying on traditional assembly, transitioning to insert molding may seem like a significant shift. But the long-term benefits—from simplified logistics to stronger products and lower defect rates—are hard to ignore.

The key to a successful switch lies in collaboration. Choosing a supplier with proven experience in insert molding for electronic applications ensures that the right materials, processes, and tooling are used from the outset.